Packaging Training

PROJECT MANAGER • RESEARCHER • DESIGNER

Opportunity

Lumi is a platform for connecting businesses with packaging manufacturers. In order to build, market and sell the software, our team needed a base knowledge of packaging, manufacturing, and sustainability.

Without a shared knowledge base, new team members were learning on the go, asynchronously piecing together new information through Google and Slack.

Execution

I launched a cross-team collaboration to build our first packaging training — Lumi U. New employees got a comprehensive overview of printing and manufacturing, in addition to the sustainability implications of each packaging product. The goal was not only to teach new team members the base packaging info that they’d need for their role, but to hopefully pass along our enthusiasm and curiosity.

Over time, we continued to iterate and refine the training to optimize for a knowledge set that would be most useful across every role and team.

Process

-

For my first year or so at Lumi, I was learning new packaging information every day. Well, come to think of it, I’m not sure that ever changed, but as our team was growing month to month, it seemed necessary to consolidate all the information we’d learned so far into a common source of truth.

To build this packaging training, I brought on our merchandising designer Lauren Tom who was responsible for all of our product pages and had an intimate knowledge of specs and customer expectations. I also brought on our head of supply chain Daniel Binkoski who was responsible for growing our manufacturer network and had a comprehensive understanding of manufacturing capabilities.

The three of us built the teaching deck and we taught most of the early sessions. Over time, we brought in a team of 10 teachers to share the load and rotate sessions throughout the year.

-

As a 1-person content team, this was usually my motto. We had so much information in our product catalog along with a gallery of YouTube videos and internal manufacturer documents to learn from. So after starting with a loose outline, the beginning of the project was all about gathering, culling, and curating. Then we’d find the gaps that we had to fill out with more information.

-

Working from our beefy knowledge base, we deliberated over how best to design the information in a way that was digestible and memorable. It’s not likely that everyone was going to remember everything that was said. It was more important that they remembered the information existed. In other words, taking people from “what you don’t know you don’t know” to “what you don’t know”.

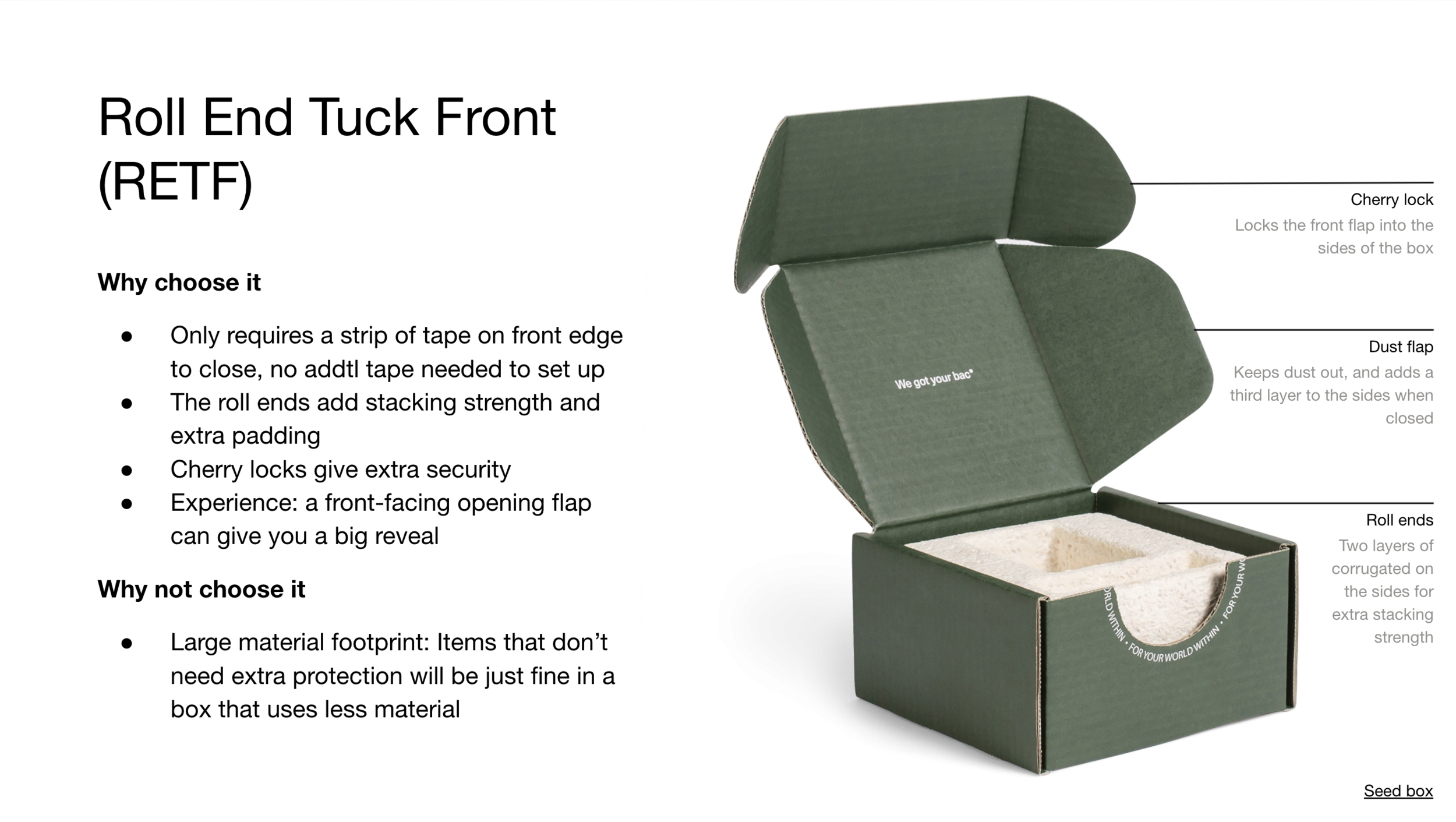

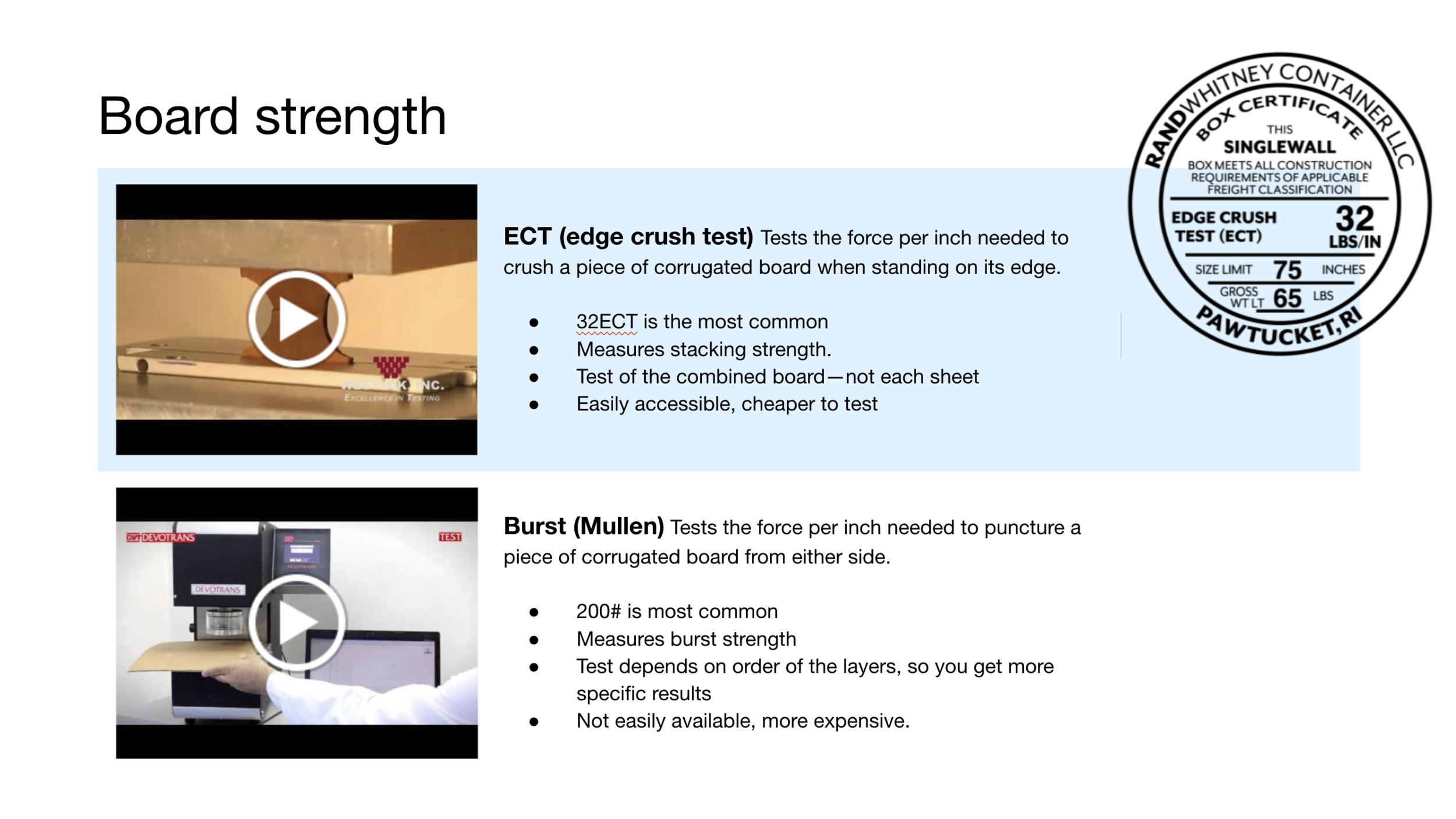

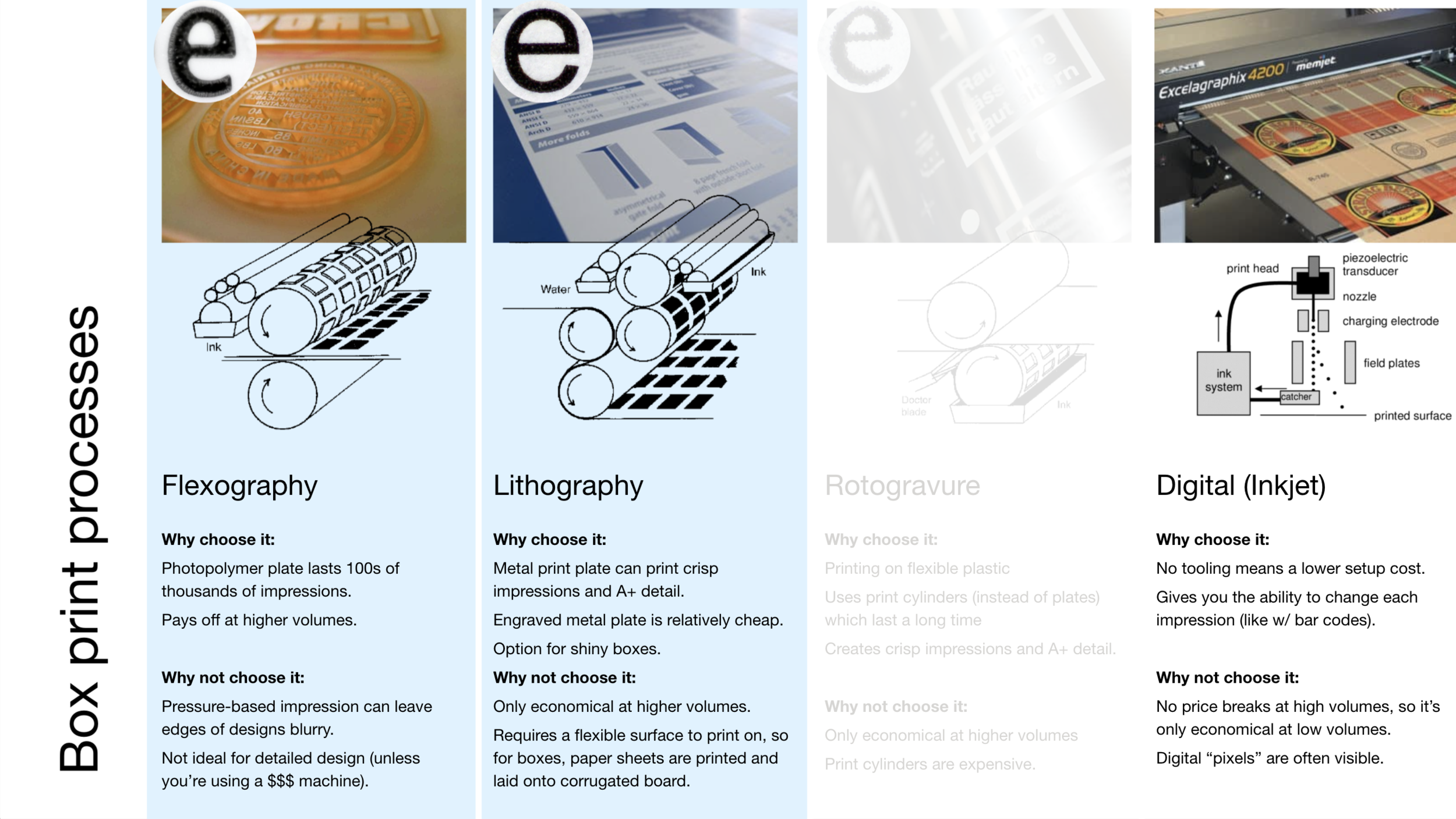

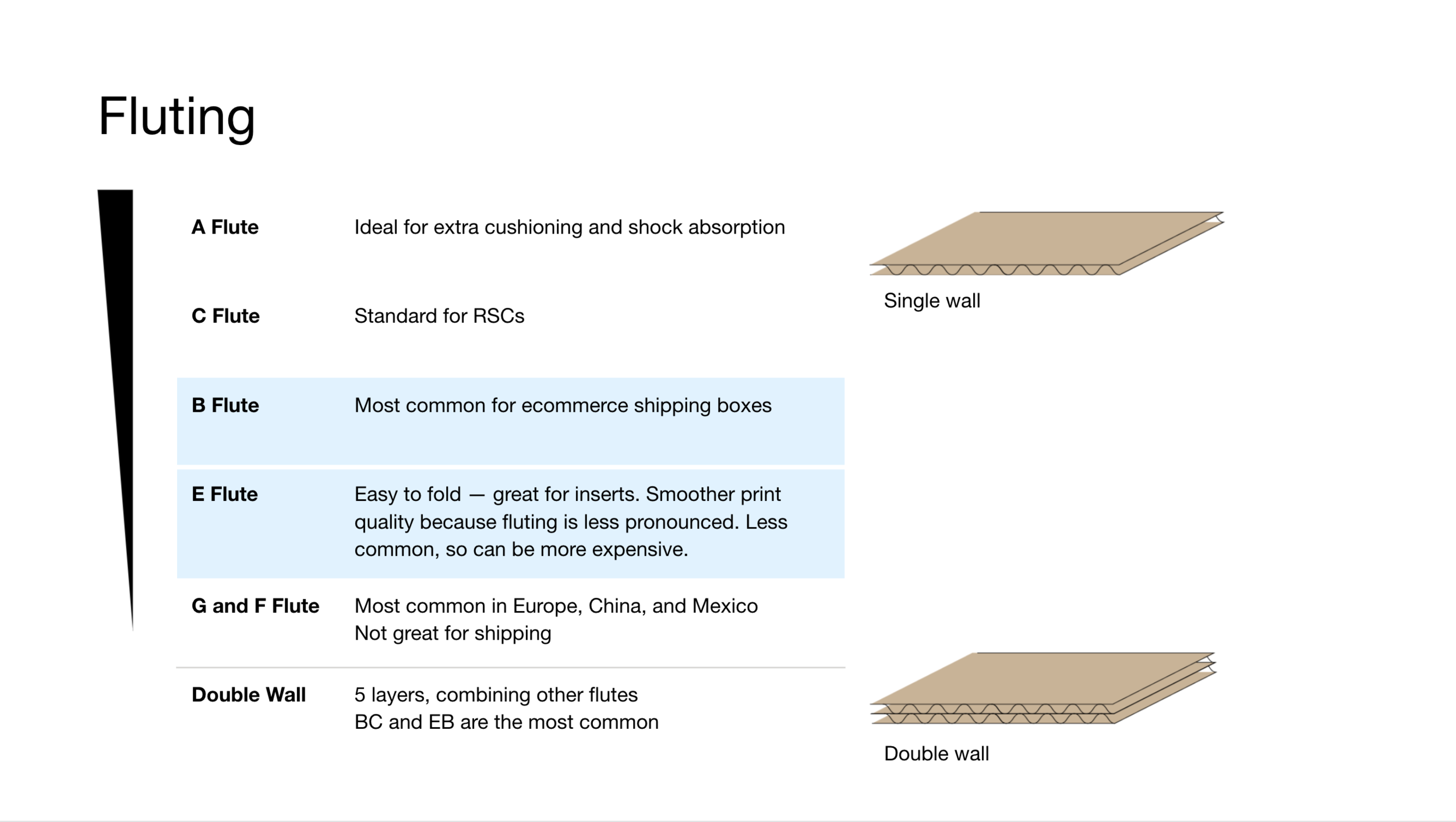

By templatizing each section of the lesson, we leaned on consistency as a strategy. Ultimately, the sections were divided by product type: boxes, mailers, tape, etc. Each product section covered styles, materials, printing processes, manufacturing, recovery, and sustainability.

-

Over time, Lumi U saw many iterations, adapting to more frequent hiring, new product categories, more advanced customer knowledge, and remote work.

The first iteration was a 100+ slide deck (complete with hands-on activities) that we collaborated on through several meetings and after-hours brewery work sessions. Each Lumi U course consisted of two 2.5 hour sessions. But after two days of teaching, it wasn’t just the teachers who were exhausted — the students were too.

It wasn’t easy, but we soon cut the training in half, ruthlessly (at times painfully) eliminating slides. It forced us to examine each section of information through the lens of various roles. Why would a person need to know this and how would they use this information? Through that lens, we were able to remove information about less popular products and print methods and prioritize more in depth knowledge about more common products.

After each Lumi U session, we gathered feedback from the teachers and updated the deck with new information based on questions they were asked or their own suggestions of how to streamline.

More projects